Many renowned spirits brands integrate brand philosophy, market positioning, and aesthetic creativity when designing new glass packaging bottles. A well-crafted glass bottle can significantly enhance a brand’s appeal and boost its recognition in a crowded market. In contrast, a generic design may cause the product to blend in, affecting sales performance.

4 Steps to Create a Unique and Iconic Packaging Bottle Shape

1. Brand Identity and Design Inspiration

Leading liquor brands often draw inspiration from their brand culture or product characteristics.

For example, when designing the Hennessy X.O limited edition, the company collaborated with top artists, using a metallic shell with irregular geometric facets to symbolize the cognac’s complex layers.

Absolut Vodka, on the other hand, took inspiration from vintage apothecary bottles, creating a short and sturdy form with a smooth, ergonomic grip, giving the glass bottle a distinctive medical aesthetic.

2. Shape and Ergonomics

When designing a new crystal vodka bottle, ergonomics and practicality are key. The glass bottle needs to feel comfortable when held, poured, and stored. Budweiser, for example, performs grip and pour tests before finalizing its bottle shape, ensuring it suits consumer handling preferences.

3. Materials and Decorative Techniques

Many premium brands also focus on materials and decorative processes to enhance their glass packaging containers’ visual appeal. Belvedere Vodka’s frosted finish and clear window panels create a visually striking contrast.

4. Market Testing and Optimization

A successful design is not only a product of creativity but also needs to pass market validation. Brands like Budweiser conduct extensive consumer testing before releasing new glass bottle designs, ensuring they meet market preferences in both aesthetics and functionality.

How to Turn a Concept into Reality with AI

All those above are the famous brand, they have the capability to collaborate with renowned designer teams. For smaller brands looking to create their own custom glass whiskey or vodka bottles, AI has made the process far more accessible to follow the design inspiration above.

Take John, the founder of a US-based vodka brand, as an example. His flavored vodkas were already popular in local bars, and in early 2024, he wanted to expand into the high-end market with a peanut-flavored vodka. After several rounds of flavor formulation, his team finalized the recipe. The next challenge was designing a bottle that captured the essence of this unique flavor.

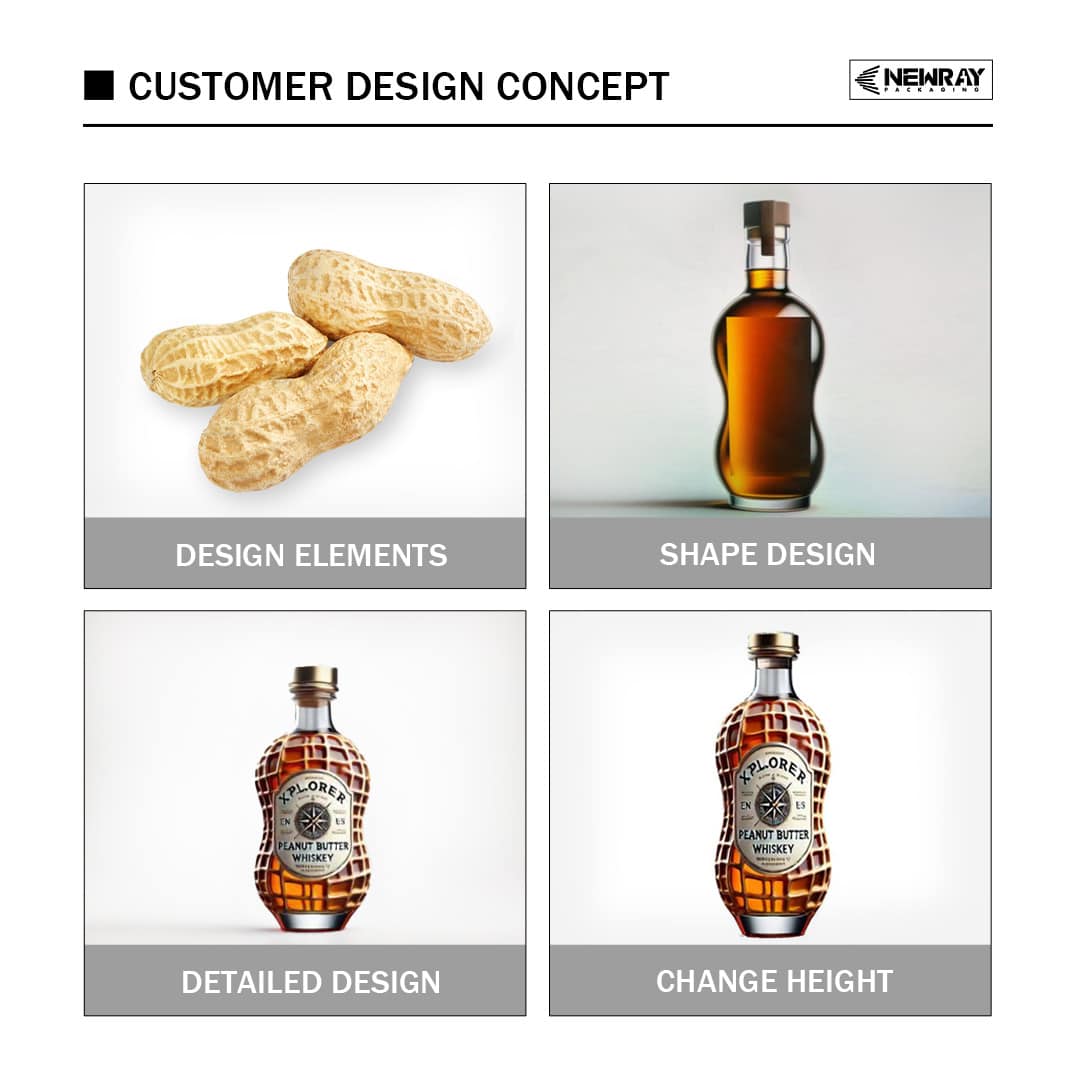

I. John’s AI-Driven Design Process

1. Inspiration and Initial Concept

- John shared two images with the AI tool: one of a peanut and another of a standard glass vodka bottle.

- He instructed the AI to create a bottle shape inspired by the natural texture and organic patterns of a peanut shell.

2. AI-Generated Glass Bottle Design

- The AI produced a sleek, elongated bottle with flowing curves, giving it an elegant silhouette.

- Thepeanut shape glass bottle for vodka surface featured a peanut-shell texture with varying depths, creating a realistic and tactile effect.

- The AI provided multiple iterations with different heights and widths, allowing John to compare proportions while keeping the 750ml capacity intact.

3. Refinement and Finalization

- Although the AI-generated concept looked promising, John found two aspects that needed improvement:

- The surface lines lacked the natural irregularity of a real peanut shell. Instead of simple intersecting lines, John wanted deeper, more dynamic grooves that varied in size and depth.

- The new designed glass bottle proportions felt too short and wide. John requested a taller, slimmer profile to give the bottle a more premium and refined appearance.

- Newray’s design team made the necessary adjustments, enhancing the surface detailing and refining the proportions.

II. Production Process with Newray

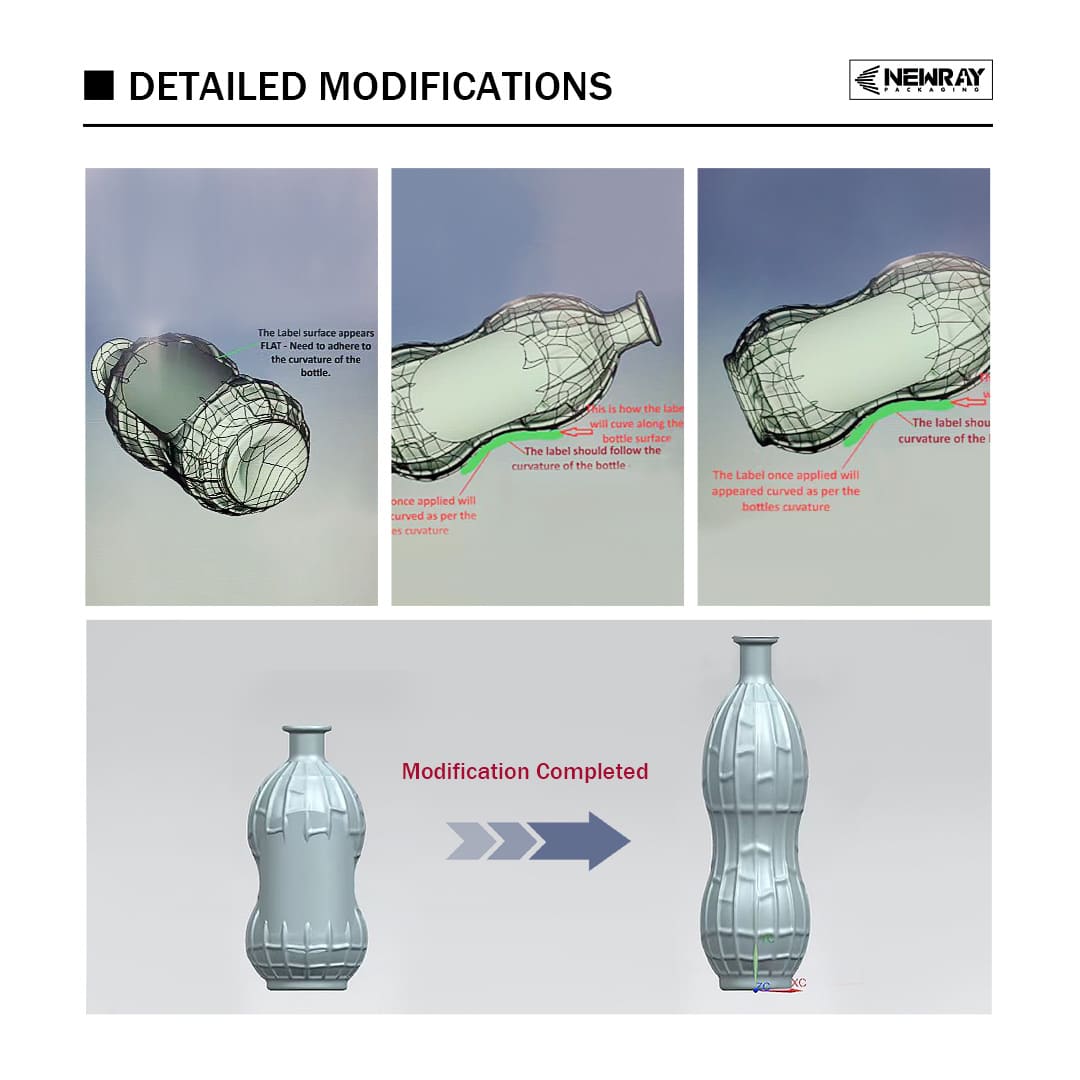

After John approved the AI-generated concept, Newray’s design team took over to transform the vision into reality.

1. 3D Modeling and Prototyping

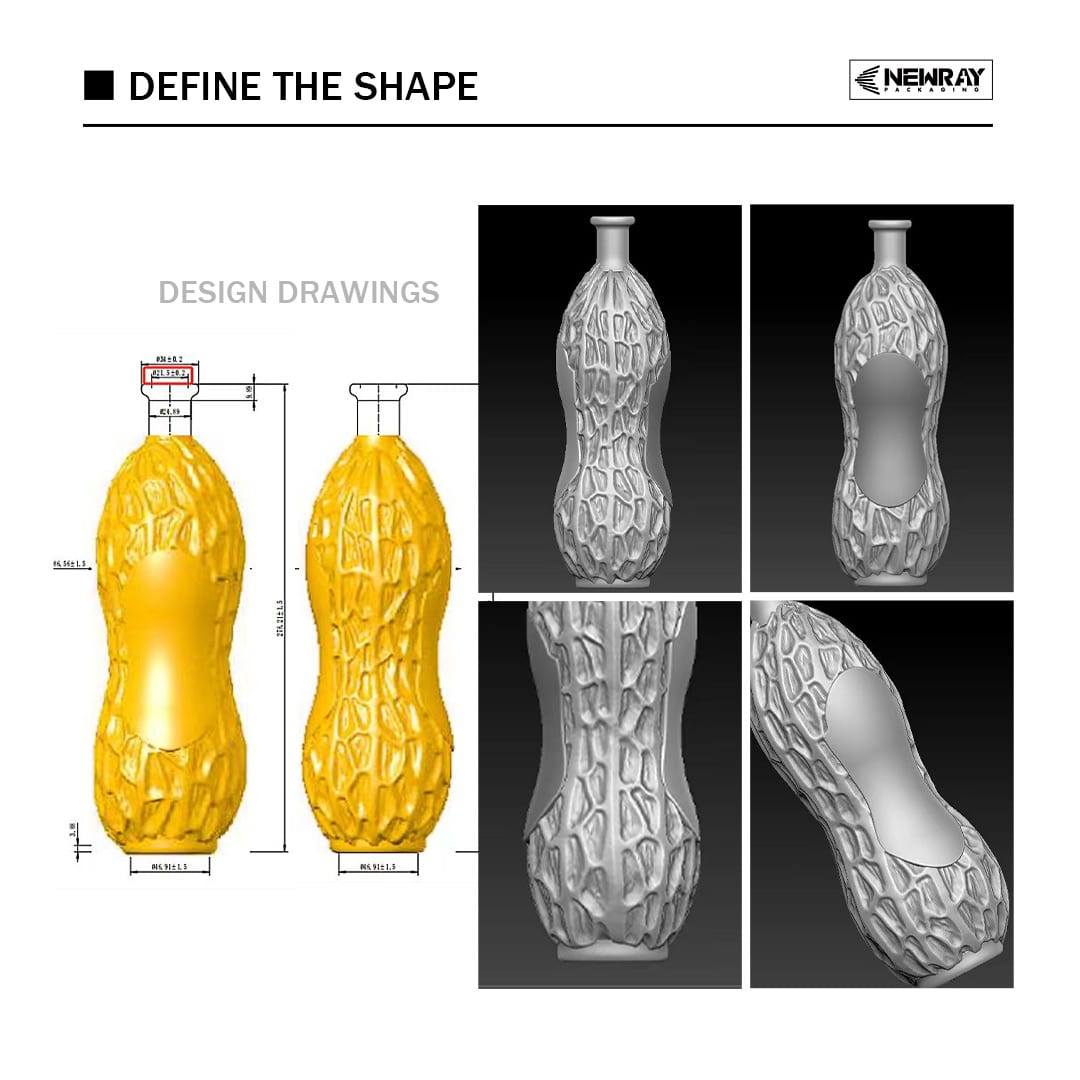

- Newray’s designers used SolidWorks, AutoCAD, orBlender to create precise 3D models, ensuring accuracy in dimensions, symmetry, and texture.

- The initial prototype was 3D-printed in resin, allowing John to assess the glass bottle’s shape, grip, and visual impact before committing to glass molds.

2. Glass Sampling and Validation

- Once John approved the plastic prototype, Newray produced a small batch of glass peanut shape bottle samples using a custom mold.

- The samples were tested for:

- Capacity accuracy (750ml)

- Neck diameter to ensure compatibility with the selected cap

- Surface quality and texture consistency

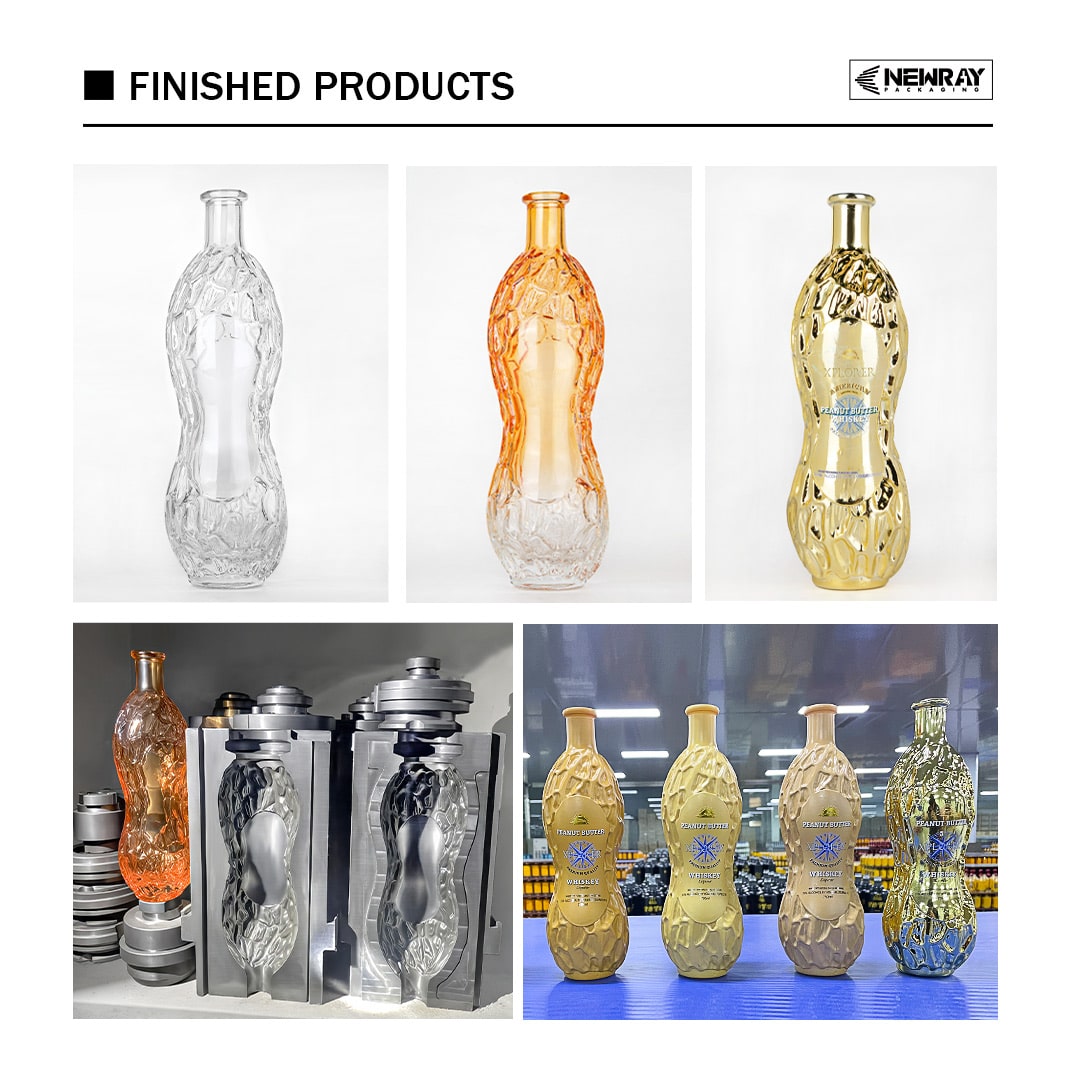

3. Color Testing and Decoration

- John was unsure which color best suited his new product, so Newray prepared over 10 color samples, including frosted, matte, metallic, and glossy finishes.

- After several trials, John selected a gold electroplated finish to reflect the vodka’s exclusivity and premium positioning.

- The final touch was a custom logo decal baked onto the vodka bottle surface, giving it a signature look.

III. Mass Production and Quality Control

Once the final design was confirmed:

- Newray moved into full-scale production, ensuring consistent quality and precise dimensions across the batch.

- The bottles were then sent to the deep processing facility for:

- Electroplating to achieve the golden finish.

- Logo application and baking to ensure long-lasting durability.

- Every new produced glass bottle underwent thorough quality control to check for dimensional accuracy, smooth surface finish, and flawless appearance.

- The final products were carefully packaged with protective wrapping and export pallets for safe transportation.

IV. Key Considerations for Custom Glass Bottle Design

If you are looking to design a new bottle, here are some key factors to consider:

1.Design Timeline

- Depending on the complexity, the process from concept to final product can take 1-3 months or longer.

- Iterations, revisions, and sampling phases add to the timeline.

2.Mold Costs

- Creating custom molds is a major expense, but it ensures the bottle shape and dimensions meet your exact specifications.

- High-quality molds guarantee dimensional accuracy and durability.

3.Minimum Order Quantity (MOQ)

- Custom bottles usually require a minimum production volume of 10,000 to 30,000 units, depending on the design complexity.

4.Regulatory Compliance

- If the glass bottle is for food or spirits packaging, it must comply with FDA, EU, or international food safety standards.

Here are the glass container for liquor customize process and timeline for you to have an overall understanding about the process time:

V. Conclusion

By combining AI-generated glass bottle concepts with Newray’s expertise in glass design, prototyping, and production, John successfully brought his peanut-flavored vodka to market with a distinctive and premium bottle design.

If you are planning to create a custom glass liqour bottle too, Newray offers:

- AI concept rendering for visual inspiration

- 3D modeling and prototyping for precise design validation

- Custom mold production with industry-leading accuracy

- Glass bottle sampling and quality control to ensure consistency

- Mass production and deep processing to achieve the desired aesthetic and functionality

Partner with Newray to bring your creative glass bottles for spirits concepts to life with speed, precision, and exceptional quality.