Table of Contents

Olive oil is widely loved by people all over the world, especially those who exercise, because it is rich in monounsaturated fatty acids and helps cardiovascular health. In 2024, due to the influence of precipitation, the global olive oil market supply is tight, and the import volume in emerging markets (the United States and China) will increase by 5%-8%. The price premium of organic olive oil is 30%-50%, and the demand in the European and American markets is strong.

According to the analysis of olive oil industry market experts, the olive oil market will show high prices, high volatility, and high differentiation in 2024-2025. Olive oil producers need to reconstruct their strategies from three aspects: climate resilience, value chain upgrading, and market diversification, and give priority to investing in technology cost reduction and differentiated products, rather than simply pursuing scale expansion.

So how can we make differentiated products? What actions can olive oil producers take from the outer packaging of their products to increase their market share? This article will discuss four aspects together and give you some professional suggestions:

Ⅰ. Why do high-end olive oil bottles need to be packaged in dark, opaque glass bottles?

In the market, consumers can observe that olive oil is usually packaged in glass bottles rather than plastic bottles. As an olive oil producer, you need to know that outer packaging plays an extremely important role in preserving the flavor of the product itself and extending the shelf life. Choosing outer packaging can help your product improve its taste in a tangible and intangible way, making it eye-catching and thus increasing market share.

So why do most olive oil brands choose glass bottles instead of plastic bottles as outer packaging for olive oil? It is mainly based on the following key reasons:

1. Chemical inertness: avoid plastic dissolution pollution

Glass bottle packaging is recognized as one of the safest packaging materials in the world. Glass (mainly composed of silica) is an inert material and will not react with fatty acids and antioxidants (such as polyphenols) in olive oil, will not precipitate heavy metals, and will not release any chemicals.

However, additives in plastics (such as plasticizers and stabilizers) may dissolve into the oil, especially in long-term contact or high temperature environments. For example, PET (polyethylene terephthalate) bottles may release trace amounts of acetaldehyde, affecting the flavor of olive oil. Olive oil may slowly dissolve certain components in plastic (such as polyethylene), causing the plastic bottle to become brittle or oil pollution.

2. Protect oil quality: reduce oxidation and flavor loss

Glass bottles can be made of original color glass. The most common colors on the market for olive oil packaging are dark green and brown glass olive bottles. These two colors are finally presented by adding colorants to the glass raw materials during the melting process, which can effectively avoid light and there is no risk of pigment precipitation.

Plastic (even high-density polyethylene HDPE) is not as good as glass in terms of oxygen barrier. Long-term storage will lead to oxidation of oils and oils, which will accelerate the rancidity and cause the olive oil to deteriorate or have odor.

Most plastics are transparent or translucent, and the bottle walls are thin, which cannot effectively block ultraviolet rays (unless special coatings are added). If exposed to high temperatures, they are easily deformed, which accelerates the deterioration of oils. Glass has a wide temperature resistance range (-10℃ to 120℃), an average wall thickness of 2mm-3mm, and colorants that effectively block ultraviolet radiation. It is suitable for different storage environments and can better protect olive oil and facilitate preservation.

3. Shelf life and quality requirements

Extra virgin olive oil (EVOO) needs to be stored for more than 18 months. Glass bottles are not easy to react chemically due to their stable chemical composition, and can better maintain the stability of their acidity and peroxide value.

Plastic bottles may absorb the aroma molecules of olive oil (such as aldehydes and esters), causing the flavor of olive oil to decay, while glass olive oil bottles will not.

4. Environmental protection and sustainability

Glass can be recycled infinitely without reducing its quality, while the recycling rate of plastic is low (especially food-grade plastic), and the recycling process may release pollutants. At present, many countries have explicitly banned disposable plastic packaging, or restricted products with plastic packaging, and imposed taxes and other measures.

Plastic bottles may produce microplastic particles during degradation or use, which may pollute oil products. Long-term use of plastic packaging may directly or indirectly bring health risks. At present, there is a general perception in the market that plastic bottles are used to pack low-end products, and glass bottles are used to pack high-end products.

5. Market perception and brand image

Glass olive oil bottles (especially dark colors) convey “natural and high-quality” signals, which meet consumers’ expectations for high-end olive oil and have a high-end symbol; plastic bottles give people a cheap feeling regardless of their own light weight or soft feel, and are mostly used for low-end or industrial oils.

If olive oil is packaged in a transparent glass packaging bottle, consumers can directly see the color and clarity of the oil itself. High-end olive oil can consider using a crystal white glass bottle as the outer packaging, which can not only show the original pure color of olive oil, but also have a certain advantage of amplifying quality. Plastic bottles are not very wear-resistant, easy to scratch or transparency will be reduced due to time and storage environment.

In summary, the comprehensive performance advantages of glass bottles for packaging various edible oils are very obvious, which also makes it the first choice for olive oil, especially extra virgin oils, while the limitations of plastic bottles are more obvious. Due to its uncertain chemical properties, it is not suitable for long-term storage of oils. Of course, glass packaging containers also have their inherent disadvantages such as fragility, etc., and it takes more cost to protect them during transportation. Olive oil brands should consider all aspects and make the final choice when choosing outer packaging.

Ⅱ. How can olive oil brands choose the glass olive oil bottle that suits them?

When choosing the appropriate outer packaging materials, olive oil brands or filling plants need to comprehensively consider product characteristics, cost, brand positioning, various local regulations, especially the safety requirements for food packaging and other factors. Below we provide you with some professional key steps and precautions from five aspects:

1. Clarify core needs

Brands need to have a clear understanding of the grade and positioning of olive oil products. If your olive oil is high-end EVOO or extra virgin, then give priority to dark colors, such as brown or dark green glass oil bottles. For higher-end products, if you want to differentiate first, you can consider customizing black, white spray colors, etc., to emphasize light-proof and logos or label deigns.

Glass bottle manufacturers can produce multiple visual effects according to brand positioning needs, such as frosted ending, hot stamping, and wood grain corks or labels to show the pure natural and pollution-free texture of the product. You can also consider crystal white glass packaging bottles to highlight the scarcity of high-end gift boxes for products.

For low-end or refined olive oil, you can consider using ordinary white transparent glass bottle packaging or high white transparent glass, which can also attract attention with unconventional label information design, and can do a lot in self-adhesive design.

Brand owners should be especially reminded to pay attention to local target market regulations. Markets such as the EU and the United States have strict standards (such as EU 10/2011) for food contact materials (such as heavy metal migration in glass). It is necessary to ensure that the outer packaging bottles meet the exporting country’s requirements for food outer packaging safety. Before you choose an olive oil bottle supplier, you need to understand whether they can provide the corresponding test report or whether they have the corresponding product certificate.

2. Selection of key physical performance parameters of olive oil packaging glass bottles

1. Color and light transmittance

Dark glass (brown olive oil bottle or green, sprayed glass: such as sprayed all black, sprayed white, etc.):

The order of blocking ultraviolet rays: black, milky white> brown, dark green> transparent material color.

Applicable scenarios for dark glass bottles or sprayed oil bottles: high-end olive oil, oil products with long shelf life

Plain white or high white transparent glass: needs to be matched with light-proof outer packaging or labels, suitable for short-term sales products.

2. Capacity and bottle design

Currently, the common capacities on the market are 100ml promotional or travel packs, 250ml (high-end tasting packs), 500ml, 750ml (mainstream capacity) and 1L&2L (family packs).

Bottle mouth design: Most of them use ROPP caps or plastic caps with plastic inner caps for pouring nozzles, and are sealed with plastic film on the outside, which plays a certain anti-theft role.

Some high-end designs use T-shaped mouths with polymer inner plugs. This bottle mouth design has higher sealing performance, but the cost is relatively higher.

3. Glass thickness and strength

If the olive oil brand is in the middle and low-end market, you can consider using lightweight bottles. Lightweight bottles can reduce the weight of glass bottles to the maximum extent. Depending on the design of different bottle types, the weight can be reduced by 10%-22%. However, before reducing the weight, pay attention to arranging suppliers to test the physical properties of small batches, such as impact resistance and pressure resistance, to ensure that the strength of the glass bottle will not burst due to pressure during the filling process, or break during stacking and transportation.

If olive oil is for the high-end market, you can consider using crystal white thickened bottles. This design will be thicker and heavier than ordinary olive oil bottles in both the bottle body and the bottom, and is more suitable for high-end gift packaging. It can be matched with high-end self-adhesive stickers that highlight the quality, or hot stamping deep processing can give consumers a more noble and high-end experience. The packaging cost and transportation cost of this type of packaging will be slightly higher, and the brand side needs to have enough budget when choosing this type of packaging.

4. Cap sealing design

Bottle cap type:

ROPP aluminum anti-theft screw cap + inner cap pouring nozzle: good sealing, suitable for long-term storage; need to purchase a special capping machine to press the thread to seal, which has an anti-theft effect. At present, there are also aluminum caps with pressed threads on the market, but they have no anti-theft effect. Please confirm the required cap type before purchasing.

Plastic cap + inner cap pouring nozzle: no anti-theft effect, if anti-theft is required, you can consider adding a heat shrink film bottle sleeve. The cost of plastic cap is slightly lower, and it is necessary to check whether the liner material is food-grade PE.

Replaceable cap design: Nozzle design: The bottle mouth is equipped with a plastic spray gun that can spray oil, which is convenient for oil control.

3. Olive oil bottle supplier screening and quality control

Key points to choose the right supplier

- Choose a glass factory that has passed ISO 9001, FSSC 22000 and other certifications to ensure the safety of food-grade production environment and storage environment.

- Investigate whether there is a traceability system. If any problems occur during the filling process of glass bottles, can the loopholes in the product production process be checked and the operation process be corrected in time to ensure that the same problem does not occur.

- Whether there is a complete after-sales system, whether the problem or dispute can be properly resolved, and provide corresponding compensation plans.

- Can third-party certification reports such as SGS and Intertek be provided for olive oil bottles?

- Suppliers with experience in the olive oil industry are given priority (familiar with bottle types and sealing requirements, and more experienced in how to package safely).

Sample testing

Light-proof test: Put the oil sample into bottles of different colors, and perform light acceleration experiments (such as UV light irradiation for 48 hours) to detect changes in peroxide value.

Sealing test: Require glass bottle suppliers to provide samples with different mold numbers, seal them with stamps, and invert the bottles to detect leakage.

Machine filling and labeling test: Require the provision of small batch bottle samples, and perform small batch filling tests, automatic capping tests, and automatic labeling tests on the filling machine. Ensure that the filling machine can perform filling and packaging normally and correctly. The bottle type can be fully matched with the machine.

Third-party inspection and testing: simulate the storage environment and detect the migration of heavy metals such as lead, cadmium, and arsenic.

Cost negotiation

Mold fee: Customized bottle types require mold fees (about 5000USD-7000USD). Some suppliers have preferential policies that refund mold fees if the number of orders reaches 3 million within 2 years. You can actively ask the supplier whether there is such a policy.

Minimum order quantity (MOQ): Usually the MOQ of the entire unit of the glass bottle factory is 100,000. It is not produced in combination with other different bottle types. It can be inspected by the camera of the automatic bottle inspection machine to ensure quality. Small batches can consider standard bottle types with inventory, but the market recognition is not high, and comprehensive consideration is required.

4. Additional functions and brand design of olive oil packaging bottles

Labels and decorations

In the design of the bottle type, a labeling area needs to be reserved. You cannot only consider the appearance without considering the difficulty of mass production. When labeling the whole body, you should consider avoiding the bottle body being completely straight. A certain degree of inclination should be left to prevent the labels from sticking to each other during the automatic labeling and filling process, causing production problems.

High-end olive oil products can be made with hot stamping, embossing and other processes. With high-end packaging, cloth bags, leather bags, gift boxes, leather gift boxes, paper gift boxes, etc., it highlights luxury.

5. Common problems and pitfall avoidance guide for choosing glass olive oil bottles

Problem 1: The bottle is fragile

Solution: Choose high-quality suppliers and reduce transportation losses from the source design. Or use a thickened design, and use 4 to 6 strapping tapes to reinforce the wrapping film.

Problem 2: Poor sealing of the bottle cap

Solution: Require glass bottle suppliers to provide product physical performance test reports to ensure the flatness of the bottle mouth, whether the bottle mouth size value is within the tolerance range, etc. Require suppliers to provide large samples with lids for testing each time they produce, and arrange shipment after they are correct.

Problem 3: Goods quality problems

Solution: Require third-party testing before shipment, provide inspection reports, and arrange shipment after inspection.

Ⅲ. What are some distinctive olive oil brands in the world that you can use as packaging references?

The following are some famous olive oil brands with unique glass bottle designs or iconic packaging worldwide, covering high-end, artistic and functional designs for reference and inspiration:

1. Italian brands: classic and artistic

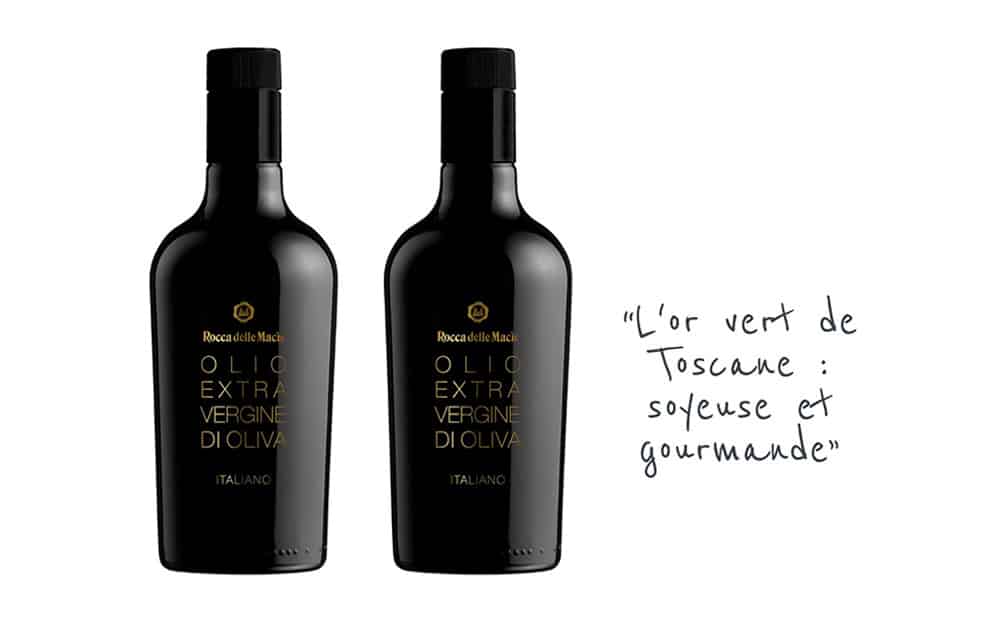

[Rocca delle Macìe]

Design highlights:

The amber glass bottle takes light shielding into consideration, and the design lines are smooth and elegant. It is matched with a wood grain bottle cap and hot stamping, highlighting the tradition of Tuscan manor. The design of wide top and narrow bottom is convenient for women to hold.

2. Spanish brands: modern and functional

[Carbonell]

Design highlights:

The classic “water drop-shaped” green glass bottle has a unique design but is different from most bottle shapes on the market, like a Spanish beauty standing in your kitchen. The bottle cap has a built-in anti-drip design, which is very practical.

【hojiblanca】

Design highlights:

The classic “Dorica” bottle saves the cost of designing a new bottle and opening a mold. The whole body is sprayed with bright white design, matched with the classic black logo design and black and white pattern bottle cover. The design is eye-catching and delicate. The metallic red hot stamping enhances the grade of the entire packaging. This design is committed to being addictive on supermarket shelves. It is highly reusable, and the bottle can be used as a vase after use, which will also be a good decoration.

3. Greek brand: minimalism and natural style

【Omed】

Design highlights:

The whole body is matte white spray glass bottle. The bottle shape is different from other square Marasca. The design is tougher and more modern visually. It is matched with olive green and imitation gold tree printing, which is unique. Silk screen printing and hot stamping logo distinguish different flavors of olive oil. The three flavors are placed on the shelf to form a complete tree shape. Using logo design to differentiate makes people shine, unique ingenuity, and the brand sense instantly goes straight into people’s hearts.

4. American/Australian brand: innovation and environmental protection

【California Olive Ranch】

Design highlights:

Square brown and emerald green pigment glass bottles + large blank labels (highlighting the simple style of “California sunshine”). This approach can be considered for large quantities and mid-range markets. The price of pigment glass is relatively low, but the minimum order quantity of bottles is high, starting at 200,000. The overall weight of the bottle is reduced by 10%, saving costs. The logo of the self-adhesive sticker is also the most economical compared to silk-screen or hot stamping on the bottle.

【Evie】

Design highlights:

Save costs and use the classic vodka bottle shape for spraying. The spray color uses the Morandi color system, giving people a fresh and sunny feeling. With the original ecological wood grain cork, it has a good sealing effect while It gives people a natural and pollution-free feeling. The bottle body is made of thick crystal white material, which feels heavy in the hand and increases the brand texture. The white logo is printed, simple, elegant and artistic. It gives people a beautiful enjoyment when placed alone in the kitchen or on the dining table.

Design suggestions:

High-end market: refer to customized glass bottle shapes, classic shape painted glass olive oil bottles, custom brand embossed logo design, hot stamping, spray color and other elements.

Environmental positioning: learn from Spanish brands and reusable design.

Cost considerations: weight reduction can reduce costs and logistics costs.

The packaging of these brands has successfully strengthened the brand value through visual recognition and user experience, and olive oil brands can flexibly adjust according to their own positioning.

Ⅳ. Boosting Global Market Share: Innovative Packaging Strategies for SME Olive Oil Brands

In the fierce international market competition, small and medium-sized olive oil brands need to break the monopoly of big brands through differentiated packaging design. The following is a detailed list of the whole process from a professional perspective, covering a complete plan from market research to implementation:

1. Market research and positioning

First, we need to analyze the packaging of competing products, collect the packaging materials, bottle types, label designs, and capacity specifications of the top 10 competing products, and use SWOT to analyze their advantages and disadvantages.

Key points to record: Design minefields of big brands such as excessive complexity and unmet needs, such as environmental protection and portability.

Brands need to make target user portraits for their own brands, segment the market (such as healthy diet lovers, high-end gift buyers, age stratification, etc.), and clarify the most important aspects of their own brands to make the final platter. Consider the following aspects: purchase scenarios (self-use/gift/restaurant purchases), price sensitivity, aesthetic preferences (minimalist/retro/artistic), cost and supply chain evaluation, and set the proportion of packaging costs.

After having a rough design, screen 3-5 glass bottle suppliers and ask them to provide:

MOQ (minimum order quantity), whether they can provide professional product design suggestions, quotation details, proofing cycle, whether the mold fee is refundable. Whether they accept inspection and factory inspection, etc. Whether they have relevant certifications or quality system certifications in the glass bottle production industry (such as ISO, EC1935/2004, FSSC22000, etc.) After a comprehensive understanding, choose one or two suppliers for proofing, and finally decide which one to buy after seeing the effect after getting the samples.

Second: Differentiated packaging design strategy

1) Bottle shape innovation

Functional design:

Pouring nozzle design, spray gun design, etc.

Design:

Asymmetrical bottle, or symmetrical label design

Reusable design (use as vase/seasoning bottle after use)

Tactile enhancement:

Embossed craft (olive leaf texture on bottle)

Frosted glass + partial bright surface LOGO

Environmental protection concept:

Lightweight glass (reduce transportation costs)

Recycled glass + plant-based ink printing

2) Label system

Information layering:

Main label (brand story + core selling point)

Sub-label (nutritional ingredients + traceability QR code)

Interactive design:

Thermostatic ink (displays the best consumption tips at low temperature)

Scratch-off coating (scan the code to participate in the olive farm experience lottery)

3) Opening and sealing experience

Patented bottle cap:

Vacuum pump head (such as the antioxidant design of Coosur in Spain)

Cork + metal lock (retro high-end feel)

4) Application of color psychology

Dark green glass + gold label (delivering natural luxury)

Transparent glass + monochrome label (highlighting the clarity of the oil body)

2. Marketing supporting design

Shelf display strategy

Special-shaped bottle design (such as flat bottle body) increases the terminal display area.

Engrave the logo on the bottle body to highlight the brand. Implant the brand concept.

E-commerce optimization

Packaging must have:

Unboxing ritual sense (such as customized seal)

Anti-seismic design for express delivery (honeycomb paper tray + bottle body cloth bag wrapping)

Origin postcard gift

Storytelling communication

Add to the label/bottle body:

Olive tree GPS coordinates

Handwritten picking date

Through the above steps, small and medium-sized brands can use packaging as a “silent salesperson” to achieve improved shelf recognition and increased repurchase rate within 6-12 months. The key is to choose 1-2 differentiation points based on their own resources for in-depth breakthroughs, and then do more updated packaging tests after obtaining new sales data, rather than comprehensive innovation, so as to steadily increase market share.

The above are some reference suggestions for the olive oil packaging industry, especially glass bottle packaging design. Of course, the choice of each packaging material has different considerations from the brand side. Some products choose vacuum aluminum cans and iron cans for better storage of olive oil. Find the packaging that suits your brand, don’t blindly follow the trend, don’t blindly pursue new, strange, and special packaging and ignore the quality of the product itself.