The recycling and recycling of glass bottles can be described as very good to our human beings. It not only saves resources and energy but also realizes waste reduction, reduces the workload of the sanitation department and saves land for landfill waste.

It is the only way to build a “no waste city”. However, China’s glass bottle recycling lacks corresponding laws and regulations to strengthen enforcement. Due to this, Chang Jiwen (the deputy director of the Institute of Resources and Environmental Policy of the Development Research Center of the State Council in China) believes that all localities are now advancing the legislation on waste sorting and should take the opportunity to incorporate the mandatory recycling and recycling of glass bottles into local legislation.

Glass bottles that are randomly discarded by the sea can easily become broken glass, which is not easily degraded in nature but also leaving a safety hazard to tourists on the beach.

1 Glass bottle recycling

Glass bottles are widely used as packaging containers for jams, beer, beverages, condiments and cosmetics due to their high barrier properties and high transparency. This is a special market where old and new bottles coexist, and most of them are old bottles. In packaging products, the production of glass bottles is one of the most energy-intensive, so it is valuable for companies to recycle and reuse their glass bottles.

Even if the glass bottle with more energy consumption is recycled, this recycling method can save 800 kg of quartz sand, 130 kg of caustic soda, 130 kg of limestone and 140 litres of heavy oil for every 1 ton of glass packaging.

As for the more energy-efficient and convenient prototype reuse methods, such as glass beer bottles, glass soda bottles, glass soy sauce bottles, glass vinegar bottles, glass beverage bottles and some canned glass bottles, it will save the cost and energy for manufacturers and environmental protection. More impressive. It can be imagined that if the tens of billions of glass bottles of beer produced in China are produced entirely from quartz raw materials, what is the number of raw materials, energy consumption and sewage discharge required.

Although white wine glass bottles and pharmaceutical or medical glass bottles are hardly recycled, these glass packaging bottles can be recycled to other useful materials, such as glass shards for building bricks, glass wool insulation, reflector materials and clothing. With decorations, it can also be used to produce sewage pipes and to make various building materials and daily necessities such as asbestos.

2 China’s waste glass recycling rate is very low

In the field of food packaging, glass containers have the advantages of beautiful appearance, high transparency, good chemical stability, strong resistance to corrosion (acid and corrosion), and easy manufacturing. Companies that produce products such as alcohol, juice drinks, and yogurt tend to be packaged in glass bottles.

However, the recovery rate of glass packaging containers in China is indeed too low. The average recycling rate of glass products in the world is close to 50%, Taiwan’s Taiwan area reaches 84%, and Germany even reaches 97%. However, the lack of attention in China’s work is a lack of relevant statistics. The reporter found only one 2006 data on the Internet. At that time, some scholars estimated that the recycling rate of waste glass in China was only 13%, far below the world average. The reason for the low recovery rate in China is due to the unreasonable setting of recycling outlets, the unsuitable recovery equipment, the uneven quality of the recycling personnel are uneven, the small scale of the recycling company and the irregular operation. On the other hand, in recent years, China’s glass bottles have ample production capacity. Enterprises may buy less new glass bottles and spend less than recycling. Naturally, they are not willing to work hard to recycle.

However, if the glass bottle is mixed with other garbage and treated by traditional landfill, it will not only waste energy, bring pollution, but also waste a lot of land resources. Therefore, from the perspective of energy conservation and environmental protection, the recycling and reuse of glass containers in the food and beverage industry are imperative, especially the use of large quantities of bottled beer and beverages. From a practical point of view, food production enterprises recycle and reuse their own glass containers, retain their original use, and avoid being discarded into domestic garbage. This is the most environmentally friendly recycling method, and it is also the environmental responsibility of food producers and this way should be undoubtedly worthy for promotion.

Of course, with a complete recycling network, consumers must also have the awareness of protecting the environment. Otherwise, without the cooperation of consumers, the recycling system will eventually only be in the form.

3 Food companies recycling their old bottles are not solid waste

On September 15th 2019, when the reporter asked about the environmental hazards of discarded glass bottles, Fang Gang, a senior engineer at the Research Center for Cleaner Production and Circular Economy of the Chinese Academy of Environmental Sciences, said: “The battle against pollution is a period of the 19th National Congress. One of the three major battles. The recycling of its own glass bottles will have a positive impact on pollution prevention and control. Because the chemical properties of glass bottles are very stable, it is difficult to decompose naturally. It takes at least 4,000 years to completely degrade in nature. The bottle also contains heavy metals such as zinc and copper, which can cause pollution to soil and groundwater. Sharp glassware fragments can cause inconvenience or even harm to society and people’s lives. Therefore, the best way to treat discarded glass bottles is to Recycling and recycling of your own glass bottles.”

Then, when the company is recycling its own glass bottles, is the old glass bottle recycled to the factory area solid waste? In this regard, Fang Gang clarified: “According to the “General Principles for the Identification of Solid Wastes” (GB 34330-2017), any packaging that can be used for original purposes without repair and processing, or after the production point has been repaired and processed to meet the country, Locally established or industry-required product quality standards and packaging for original use may not be managed as solid waste. Therefore, when the company recycles its own glass bottles, it retains its original use. These used old glass bottles should not be disposed of as solid waste.”

4 Mandatory recycling is the trend of the developed countries

Make a general survey of the world, the recycling of glass containers has been incorporated into the relevant legislation for urban solid waste recycling in many developed countries, and is enforced through the deposit system, etc., with a relatively complete system guarantee. In North America, for example, in 1970 BC became the first region in Canada to impose a mandatory deposit system for soft drink bottles and beer bottles. Due to its good operational performance, this system has been adopted in almost all provinces and territories in Canada (except the Nunavut territory).

The 10 states that implement the glass bottle mandatory deposit system in the United States, although the time passed by the states is different, are generally incorporated into the urban solid waste recycling regulations and are therefore mandatory.

In the 1990s, Japan’s Law on Energy Conservation and Promotion of Recycling and Container Packaging Recycling Law determined the responsibility of manufacturers in the recycling of containers such as glass bottles and plastic bottles and presented them to consumers and producers. Mandatory requirements: Consumers must place glass containers in specialized sorting bins, and manufacturers must recycle these well-defined glass containers in place. After the implementation of these laws, the recycling rate of Japanese glass beer bottles reached 97%, and the recycling rate of glass rice wine bottles reached 81%.

5 Chang Jiwen said Mandatory recycling should be included in local legislation

The current Law on the Prevention and Control of Environmental Pollution by Solid Waste imposes legal restrictions on the recycling of packaging waste, and provides legal requirements for producers, sellers and importers of packaging materials, and provides a legal basis for the extension of producer responsibility system.

According to the “Promoter’s Responsibility Extension System Implementation Plan”, the State Council issued [2016] No. 99, the company has the responsibility to regulate the recycling of waste products and packaging through direct recycling, joint recycling or entrusted recycling, direct disposal or disposal by professional enterprises. Responsibility for product recycling and processing can also be achieved by means of production companies paying relevant funds in accordance with the law and subsidizing professional enterprises. However, this law only gives a general requirement for the handling of packaging materials, and does not propose refinement requirements, and can not truly implement the producer’s recycling responsibility.

On September 16, 2019, Researcher Chang Jiwen told reporters: “With the deepening of garbage sorting work, glass bottles as a security risk to society can be According to the principle of extension of producer responsibility, it is necessary for enterprises to strengthen the recycling and recycling of their own glass bottles. In this case, the old glass bottles are recycled by local enterprises and their trusted third parties. It is not general household garbage. Enterprises recycle it, retain the original use, and also greatly save the cost of environmental protection. So, what method is adopted to promote recycling? I think it should be adapted to local conditions. For beer bottles, or other glass products of large-scale and standardized, enterprises can be encouraged to use the deposit system to recover, that is, to allow consumers to pay a certain deposit, and then return the deposit to the consumer after the consumer returns the glass bottle. For some non-uniform, scattered glass bottles, such as enterprises are not local, you can take Other methods, such as letting consumers send to designated classified trash cans or waste collection stations to launch. In any case, it is necessary to strengthen legislation in a rule of law society with strong environmental awareness. Local governments are now advancing legislation on waste sorting. In the legislation, the mandatory recycling and recycling of glass bottles will be included, in order to promote the standardization of glass bottle recycling work and the long-term recycling work.”

6 Suzhou has put in 89 waste glass intelligent recycling barrels in the urban area, which greatly improved the recycling efficiency of waste glass, which is the first time in China.

The classification and recycling of waste glass have always been a difficult point in urban management. Suzhou actively explored and formulated the “Implementation Plan for the Recycling of Low-value Recyclables (Waste Glass) in Suzhou City”. Currently, 590pcs of special recycling bins for waste glass has been put into the urban area, including the waste glass smart that was first used in China. 89pcs of recycling bins, with overflow status reminder, abnormal movement reminder and other functions, greatly improving the recycling efficiency of waste glass.

The appearance of the waste glass intelligent recycling barrel is not much different from that of the general garbage bin. The barrel is printed with the word “glass” and the recycling hotline. The lid is locked, and a circular inlet is left in the centre of the barrel to let the waste glass be put in.

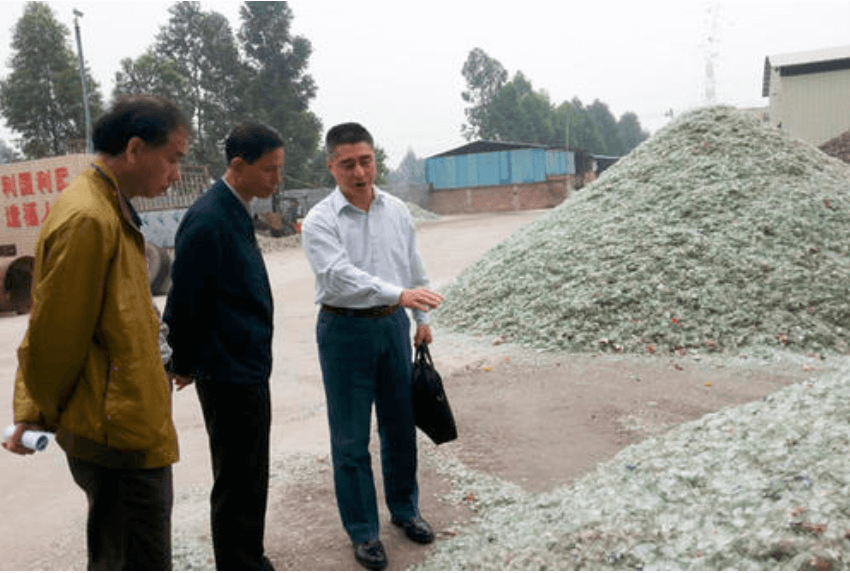

At present, 590pcs of special recycling bins for waste glass has been put in government agencies and community recycling service points, and 6 collection points have been set up. Professional recycling services for uncontaminated medical glass products have been provided for 20 hospitals and 130 clinics. According to statistics, since May last year, “Su Re-investment” has totalled 1643.7 tons of waste glass, and the recycling market share has exceeded 50%. By the end of this year, it is estimated that more than 5,000 tons will be stored. The recycled waste glass will be transported by Su-Re-investment to the Zhili Renewable Resources Industrial Park and disposed of by professional disposal enterprises.

At present, the recycling and disposal of waste glass still face the situation that the disposal and disposal costs and the sales of the unified goods are upside down. On the one hand, it is necessary for the government to provide financial guarantees. On the other hand, it is necessary to further guide the units, enterprises and citizens to raise the awareness of waste glass recycling.

7 Waste glass recycling prospects

Shanghai is striving to explore a sustainable development path that is consistent with the characteristics of a large city. It is understood that Shanghai has built the world’s largest production capacity, the highest degree of automation, the most complete selection of production and processing lines, built China’s first “urban minerals” demonstration base with waste glass recycling as the core.

Wang Qinghua, chairman of Shanghai Yanlongji Renewable Resources Utilization Co., Ltd., which was included in the demonstration base, said that the system introducing German technology can control the glass impurity content after sorting and disposal to 3‰, and can also use waste glass according to colour. Subdivided into transparent, pure white, brown, green, and so on. Due to the fine sorting and low impurities, the value of these waste glass can be greatly improved after being recycled. With the completion and commissioning of 4 automated sorting lines, the company will form an initial 650,000 tons/year broken glass recycling processing capacity to completely solve the problem of broken glass recycling in Shanghai and surrounding areas. This intelligent waste glass sorting and disposal system saves the manual work to the greatest extent, changes the dependence on the washing in the previous broken glass sorting process, and creates the “dry cleaning” sorting method, which improves the sorting efficiency and quality. Solved the pollution problem of wastewater treatment.

8 Glass recycling, environmental protection need everyone to work together

It is now a good opportunity for China to comprehensively promote the classification of waste. In the past 20 years of preparatory work, many cities have found many problems. The series of laws and regulations should be followed by cultivating the public’s awareness of waste classification and improving the facilities for waste sorting, forming a long-term mechanism for waste sorting. Environmental protection waste glass recycling, garbage sorting, etc. all require the participation of governments, enterprises and consumers. The production lines of the NEWRAY PACKAGING glass factories are also actively responding to the national call. In the production process, the quality of the products is guaranteed and some of the recycled glass is consumed. It contributes to the environmental protection cause and provides convenience for everyone while not forgetting to protect our earth. LET’S DO IT TOGETHER!