Table of Contents

Tinplate twist off caps are made of tin iron and usually used to seal honey, canned food and beverages. Tinplate technology originated in Europe in the early of 19th century, initially used for making tableware and household utensilsThey are widely used in different food packaging because they can effectively block oxygen from entering the bottle and extend the shelf life of food. The food-grade plastisol gasket inside the bottle cap is suitable for heat sealing and cold sealing, and the high-temperature gasket can be used for pasteurization processes commonly used in food.

Customers can customize tinplate caps by using glossy and matte coatings, pattern designs, colors and cap contours to further enhance their packaging appeal or function.

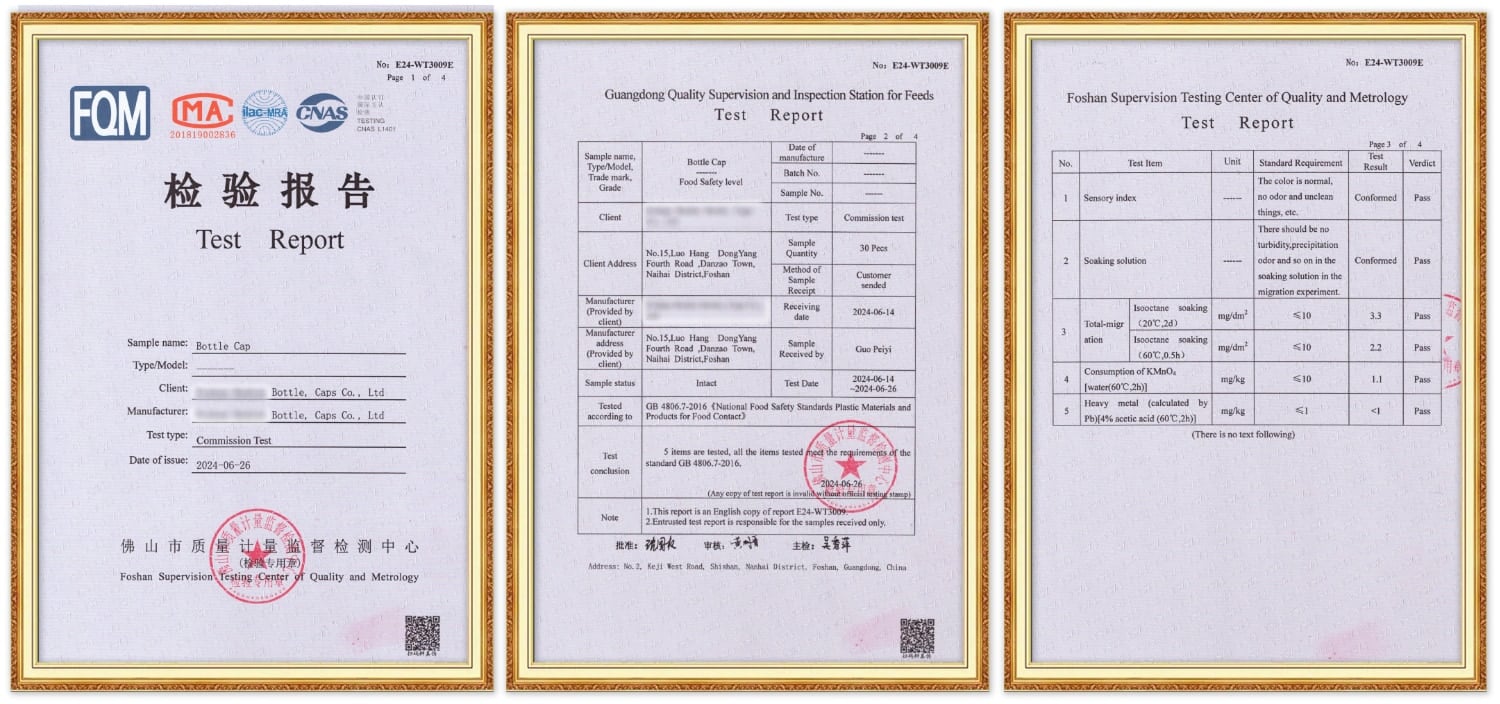

Ⅰ. Introduction of the Twist Off Cap Production Process

The under are 8 steps to produce tinplate closures for glass pickled vegetable jars and food beverage glass bottles:

1. Material Preparation

First the tinplate will do inner Coating and outer coating:. Inner coating is to apply food-grade coating to the inner side of the lid to prevent corrosion and contamination. While outer coating is apply decorative coating or print brand logos on the outer side.

Cap factory will select tin-coated steel sheets that meet standards, typically with a thickness of 0.15mm to 0.30mm.

2. Tinplate Cutting

Cut the tinplate coil into appropriately sized sheets according to the lid dimensions.

3. Stamping

Use molds to stamp the cut tinplate sheets into lid shapes, including the top and curled edges.

4. Curling

Curl the edges of the lid to enhance sealing and strength.

5. Gasketing

Inject sealing compound (plastisol gasket) into the inner edge of the lid to ensure a tight fit with the jar mouth.

6. Drying

Cure the gasket using drying equipment to ensure adhesion and durability.

7. Inspection

Check the dimensions, coating, and sealing performance of the lids to ensure compliance with standards.

8. Packaging

Package qualified lids according to specifications, ready for shipment.

Through these steps, tinplate lids for pickled vegetable jars that meet requirements can be produced.

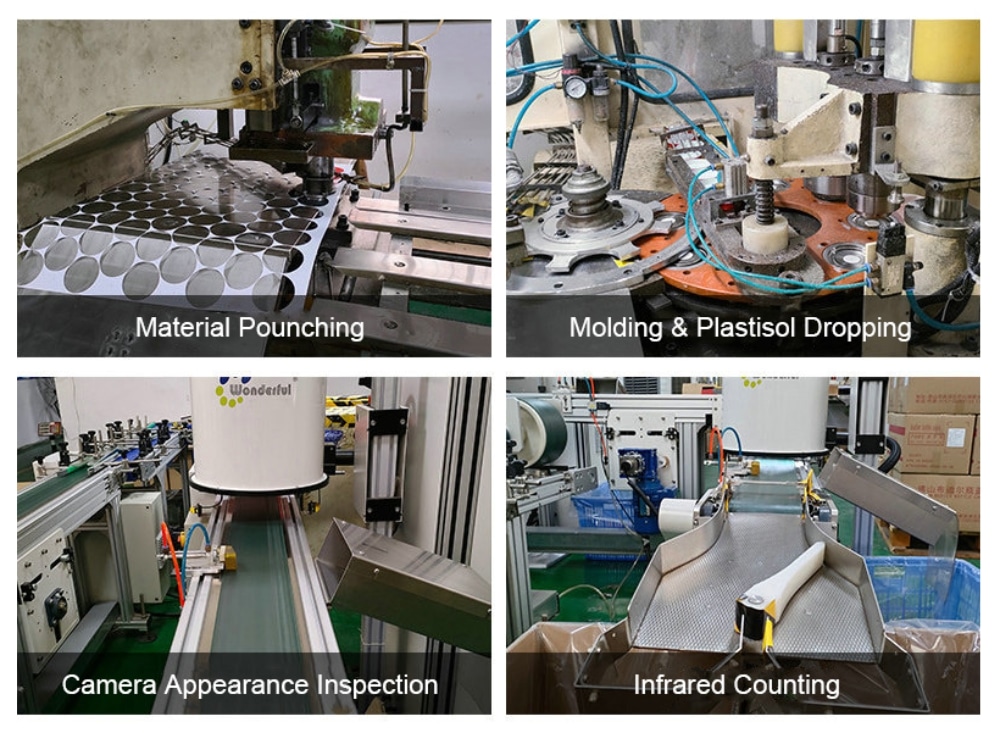

Ⅱ. Introduction of The Cap Styles & Sizes

Closures are produced according to GPI (Glass Packaging Institute) standards.

Cap Sizes, Styles & Dimensions:

| ITEM | Style | Diameter (mm) | Height (mm) |

|---|---|---|---|

| 30 | MTO, MTB | 33.55 | 12.65 |

| 30 Deep | DWO, DWB | 33.55 | 14.5 |

| 38 | RTO, RTB | 42.05 | 9.65 |

| 43 | RTO, RTB | 44.75 | 8.6 |

| 48 | RTO, RTB | 49.85 | 8.6 |

| 53 | RTO, RTB, RTS, RSB | 56.25 | 9.7 |

| 58 | RTO, RTB, RTS, RSB | 60.15 | 9.7 |

| 63 | RTO, RTB, RTS, RSB | 66.35 | 9.7 |

| 63 Deep | DWO, DWB | 66.35 | 14.5 |

| 66 | RTO, RTB, RTS, RSB | 69.25 | 9.7 |

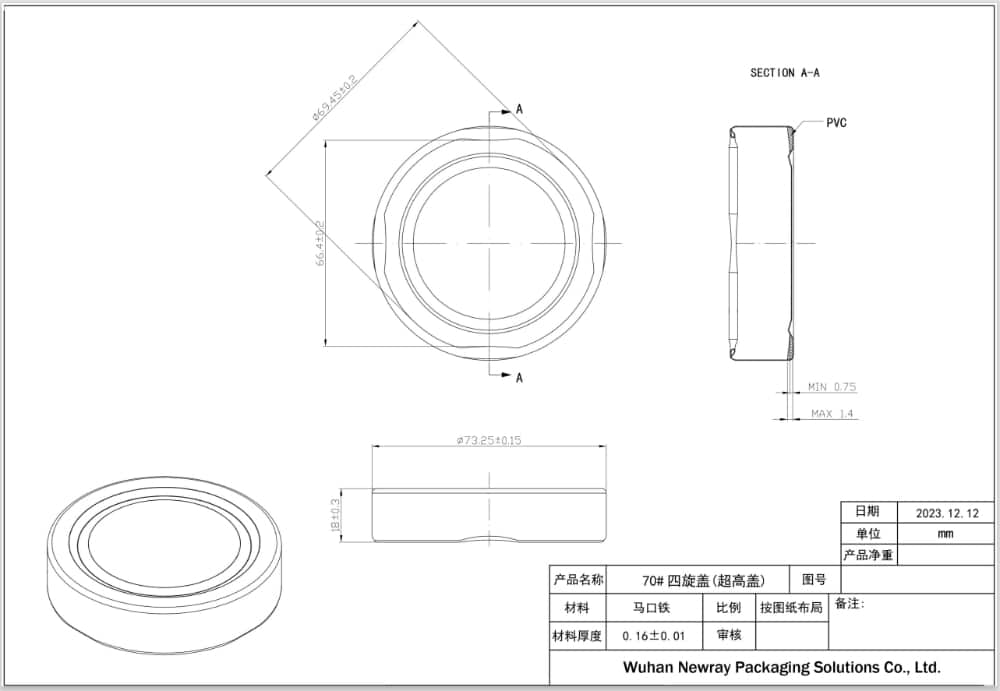

| 70 | RTS, RSB | 73.25 | 9.7 |

| 77 | RTS, RSB | 80.03 | 9.8 |

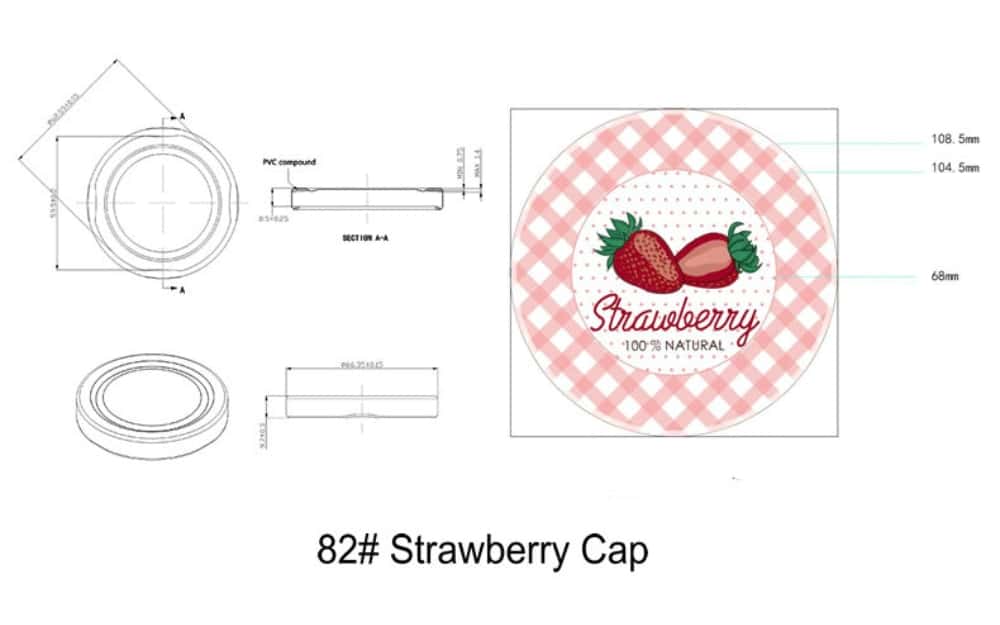

| 82 | RTS, RSB | 85.05 | 10.9 |

Ⅲ : Types of Plastisol Gasket

The glue for tinplate cover is divided into high temperature plastisol (resistant to 121degrees) and low temperature plastisol (resistant to 100 degrees) in terms of temperature tolerance. high temperature plastisol can be used for pasteurization processes commonly used in food.

It is divided into water-based glue and oil-based glue in terms of glue properties. The main difference between the two types of glue is whether the customer’s content is oily or water-based. The appearance and shape of the glue are basically the same, but the formula in the glue is slightly different. Oil-based glue is mainly used on oil-containing foods, and water-based glue is mainly used on oil-free foods.

It is divided into half plastisol and full plastisol gasket in terms of glue dripping method. Half-plastisol is a common style on the market, used for ordinary sealing, and the contents do not contain strong acids. Full plastisol is to cover the entire surface of the lid with PVC plastisol gasket to prevent strong acid contents from corroding the inner surface of the lid and rusting, preventing rust from contaminating the food in the bottle.

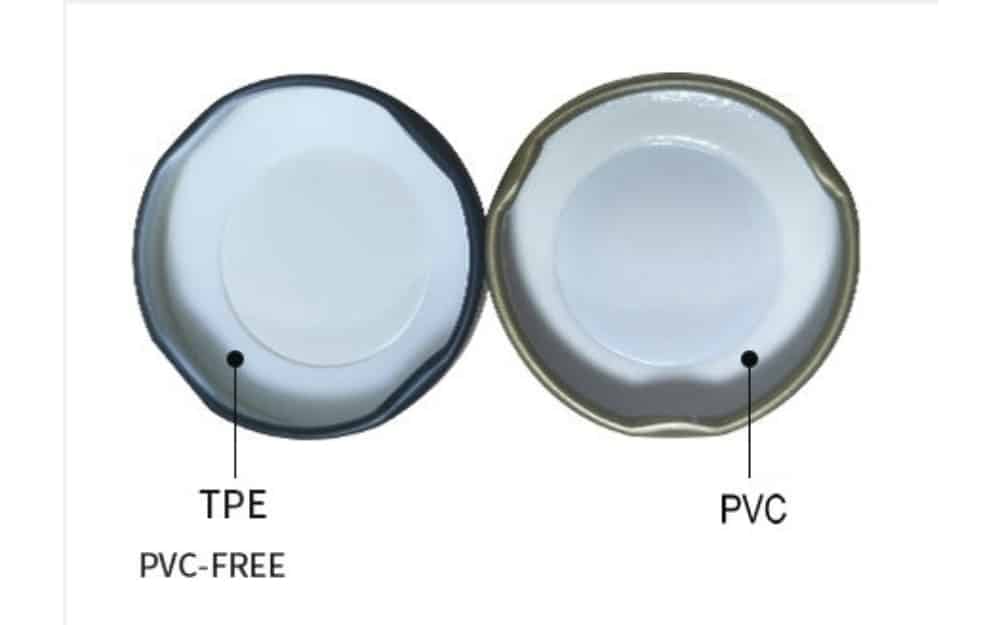

Some customers in Europe and American may requst the Non-pvc Cap, this will require the tin lid use the TPE seal. TPE does not belong to plastisol dripping, but is a kind of gasket. The accurate description should be the sealant for tinplate cover, which is divided into PVC and TPE in terms of material.

Ⅳ. How to make a high-quality tinplate cap?

1. The raw material of the iron sheet of the lid is tin-plated deep-drawn iron, which is resistant to stretching and has good anti-rust performance. The special printing process does not damage the gloss and is not matte.

2. The paint process of the lid surface uses imported environmentally friendly paint, and is printed with domestic advanced equipment. The color is bright and bright, does not fade, has good texture, and the color and pattern can be customized.

3. International universal lid type, different sizes and specifications are optional, and three-claw, four-claw, and six-claw designs are used according to the size.

4. The primer inside the lid uses professional anti-rust paint + internal coating to ensure food safety.

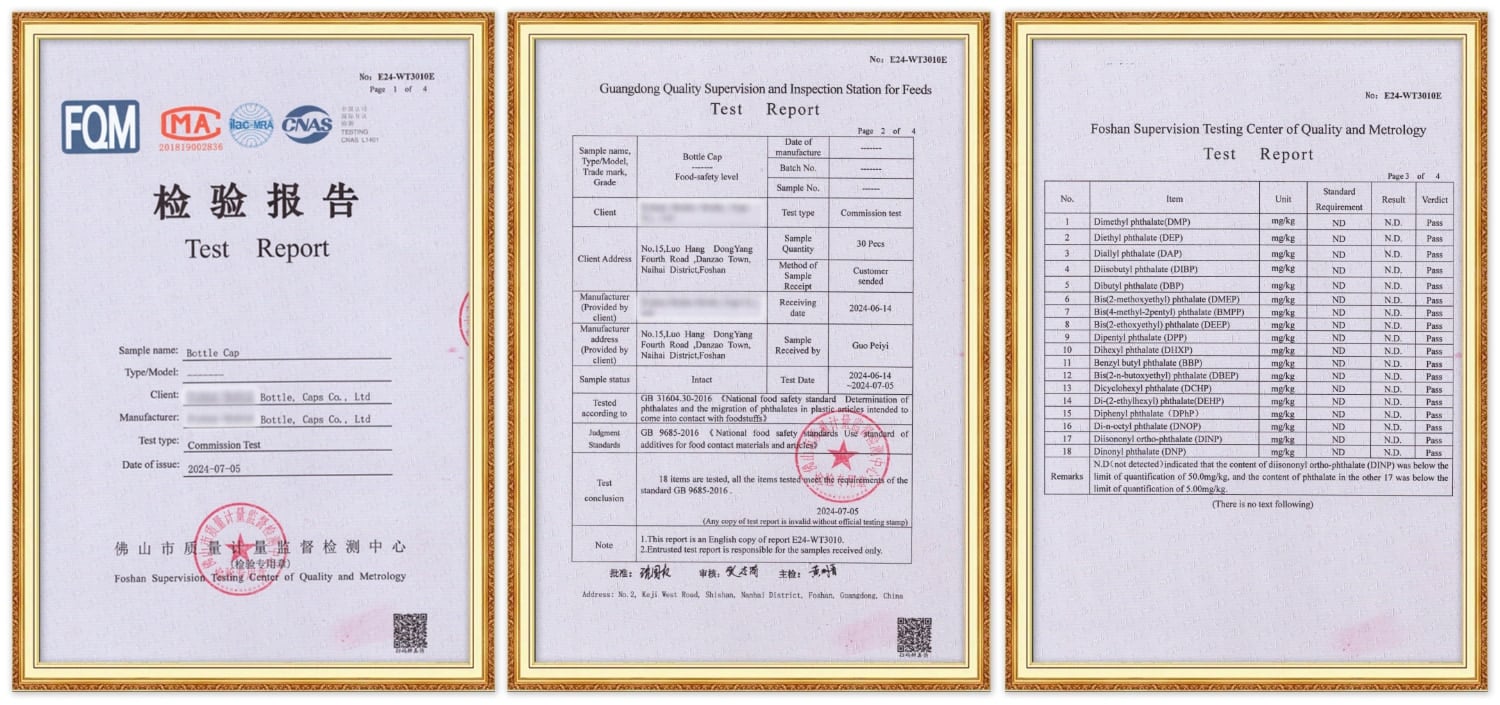

5. The glue inside the lid uses different sealants according to the different contents of the filling and the different sterilization temperatures to ensure airtightness. And it is officially inspected every year, and all meet the hygiene standards and phthalate requirements.

Ⅴ. About Safty Button

Why do some tinplate lids have safety buttons, while others do not? What is the role of this safety button?

The safety button (also called safety button or vacuum button) on the tinplate lid is mainly used to indicate the sealing and safety of the package. The specific functions are as follows:

1. Indicating the vacuum status

With safety button: Usually used for vacuum-sealed packaging (such as canned food). If the button in the center of the lid is raised, it means that the package may be leaking or not sealed properly; if the button is sunken, it means that the vacuum state is good and the product is safe.

No safety button: Mostly used for non-vacuum packaging or products that do not require vacuum indication (such as some beverage bottle caps).

2. Ensure product freshness

With safety button: Help consumers judge whether the packaging is intact and ensure that the food or beverage is not contaminated or spoiled.

No safety button: This type of packaging usually relies on other methods (such as sealing strips) to ensure product safety.

3. Prevent secondary contamination

With safety button: Once the package is opened, the safety button will pop up to remind consumers that the product has been opened to prevent secondary contamination.

No safety button: Usually used for disposable packaging, which cannot be restored to its original state after opening.

4. Different application scenarios

With safety button: commonly used in canned food, baby food and other products with high sealing requirements.

Without safety button: mostly used in beverage bottle caps and other products with low vacuum requirements.

The main function of the safety button is to indicate the sealing and safety of the package, and help consumers judge whether the product is intact. Whether a safety button is needed depends on the sealing requirements of the package and the characteristics of the product.

Ⅵ. How to test the cap?

Correct use of safety button cap: Try not to test directly with cold water or wait for 2 hours before testing with cold water. Otherwise, the cap is prone to leaking. Try to test with hot water. Customers must choose caps with safety buttons because they need high temperature sterilization or other purposes.

If the cap has a safety button, it needs to be tested with boiling water. First, fill the bottle with hot water, then seal the cap, and wait for the water in the bottle to cool naturally. After cooling, if the safety button of the tinplate cap can be sucked down normally, it means that the fit between the cap and the bottle is fine, because a vacuum state has been formed, and the bottle will not leak, so there is no problem with preservation.

Low-temperature glue caps are tested with cold water and need to be left alone for 2 hours. Why do you need to leave it alone for two hours? Because if it is cold water, there is no vacuum. After filling the cold water and sealing the cap, the bottle mouth has not yet been pressed out of the glue groove that fits the bottle mouth by the glue dripping from the inside of the cap. It is unreasonable to shake the cap to test whether it leaks or not as soon as it is covered. Most caps will leak. The correct way to test the bottle cap with cold water is to seal it with the bottle mouth facing upwards and let it stand for two hours. After two hours, wait for the glue dripping on the bottle mouth and the inside of the cap to form a glue groove before testing.

Ⅶ. Why do cap manufacturers need to know what your caps are used to seal?

The two major factors that make the tinplate cover seal perfectly are the first, the cover of the right size, and the second, the glue. Different contents require slightly different glue components and foaming methods. The cover factory knows what kind of glue is most suitable for your product only after knowing what kind of content your cover is used for sealing, whether high-temperature filling is required, whether the content contains oily substances, whether it is a strong acid product, etc.

Professional tinplate cover manufacturers have strict control over glue materials. They purchase different types of PVC glue from sealant manufacturers. These glues are divided into high-temperature low-cannon, high-cannon micro-cannon, etc. according to different foaming methods. Different glues have different codes. The cover factory will distinguish what kind of content is suitable for sealing according to these different foaming methods, such as seasoning glue, fruit glue, and oil-consuming glue.

Seasoning glue is used when the content that customers pack is condiments, sauces, and pickles. Fruit glue is mainly used by customers to seal some canned fruits with this cover, ordinary acid-free and oil-free beverages. There is also fermented bean curd glue, which is used to pack fermented bean curd.

The capping factory will also distinguish between high-temperature oily glue. This is mainly because the customer needs 121 degrees high-temperature pasteurization, and its contents contain oil. At this time, the capping factory will use high-temperature oily glue. The high-temperature water-based glue is used by customers to pack the contents without oil, such as ketchup, coconut milk, or other foods that do not contain oil and need 121 degrees high-temperature sterilization. Some capping factories will also distinguish between oyster sauce glue. The oyster sauce glue is used by customers to pack oyster sauce. The commonly used 30# smallest tinplate cap, such as Haitian oyster sauce and Lee Kum Kee oyster sauce, is the type of oyster sauce glue we distinguish.

The above are the more popular distinctions within professional capping factories. After they receive the PVC glue from the sealant factory, they will mark the distinction of these glues under the code of the outer packaging barrel so that they will not use the wrong sealant during production. Some workshop-type capping factories will use a kind of glue to conquer the world, adding a lot of foaming agent to the sealant to make the glue look full. However, if too much foaming agent is added, there will be many small pores. The elasticity of the rubber ring is sufficient, but it is not suitable for all customers’ production processes. In addition, the treatment of anti-rust paint may cause rust during the use of the lid, causing great losses to the user.

The correct approach is to understand the nature of the customer’s content and sterilization method and use the corresponding drip glue, and try to meet the requirements of different food lids to ensure that they are safe and hygienic after sealing, and there will be no migration of harmful substances or precipitation of heavy metals.

Ⅷ. How to avoid purchasing poor-quality tinplate lids?

1. Weigh the weight: For lids of the same size, look at the weight. Lids produced by bad factories generally use thinner iron sheets.

2. Look at the glue: For high-quality lids, the glue inside the lid is smooth and flawless. For lids produced by bad lid factories, the glue is over-foamed, too soft, or has miscellaneous, uneven glue dripping, and inconsistent shapes.

3. Look at the lid surface: The color of the coating on the surface of high-quality lids is oily and has no color deviation. The lids of bad lid factories are also made of small workshops because the raw materials for printing iron are also from small workshops, so the color difference can be judged at a glance.

4. Ask for drawings: Each lid of a regular lid factory has corresponding drawings archived, while the basic drawings may not be provided by the workshop-type lid factory due to chaotic management.

5. Request for certificate: Is there a food-grade inspection certificate for glue dripping, a factory hygiene certificate, a heavy metal precipitation inspection report for the lid, etc.

Therefore, food manufacturers should pay attention to the fact that when purchasing glass bottles and matching tinplate caps, you must not only compare the product prices, but also use the various dimensions listed above to judge from a professional perspective whether the caps provided by your supplier meet your needs and the food hygiene requirements of your local market. Don’t lose the big picture for the small, and be sure to choose high-quality caps produced by professional cap factories.

Ⅸ. The process of custom a twist off cap.

1. The customer provides the size and twist off lug lid design and selects the cap style.

2. The cap factory offers the lug lid design drawing for the customer to confirm

3. After the customer confirms and arrange sampling fee, the factory arranges sampling.

4. When samples ready, they will be sent to the customer for testing and confirmation that the sample meets the requirements.

5. The customer pays the advance payment, and the factory arranges production and makes bulk goods.

6. The factory sends the bulk sample to the customer for confirmation and arranges to collect the final payment and make bulk goods.

The above all are about tinplate caps. If you have other questions, please leave a message in the comment area. We will answer them one by one.